Here are some lesser used Kannas. Most of these Kannas are used mainly for shrine and temple works. Building a house may require 10 steps. But for Shrines and Temples, the same 10 steps are broken into 0.1 steps. Simply put, Shrines and Temples require 10 times more processes than a house. These Kannas were all hand-crafted by the Master when he was working for the Ise Jingu Grand Shrine.

内丸鉋 Uchimaru Kanna

内丸鉋 Uchimaru Kanna

This Kanna is used for making a rounded surface (mostly pillars) by having the Dai (body) and the blade curved. But this also means one Kanna can make only a certain size.

Sharpening the blade requires a shaped sharpening stone.

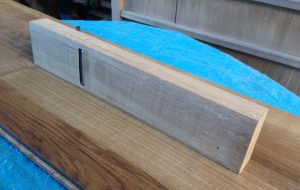

長台鉋 Nagadai Kanna

長台鉋 Nagadai Kanna

The Dai (body) of this Kanna is extra long. This provides extra stability, therefore used when a precisely flat surface is required.

大鉋 Oo Kanna

大鉋 Oo Kanna

This is used for wider wood which require a clean finish. Using this Kanna, the wood can be finished in one go. The common blade width is 3寸 (9cm) to 5寸 (15cm). Some even go up to 1尺 (30cm).

You may have noticed the blade looks different from the norm. This blade was taken from a planing finish machine. Apparently, the blade cuts really well but takes skills to sharpen and set up.

小口鉋 Koguchi Kanna

小口鉋 Koguchi Kanna

It is also known as a Dōtsuki Kanna (導突鉋). The blade sticks out on one side – either left or right. It is used to shave the end grains. It can also be used for shaving the inside part of a L-shaped area.

At first glance, it is very easy to mistaken it with a Kiwa Kanna (pictured on the left). The difference is that this Kanna uses a blade similar to the Hira Kanna but tilted at an angle. The other difference is that this Kanna is designed so that the edge cuts last, opposite of a Kiwa Kanna.

作理鉋 Shakuri Kanna

作理鉋 Shakuri Kanna

It is narrow in shape, and has the blade sticking out from both sides. This allows it to clean the bottom of the grooves used for the sliding doors and shōji. Also known as Sokotori Kanna (底取り鉋).

底さらい鉋 Sokosarai Kanna

底さらい鉋 Sokosarai Kanna

This Kanna is used to clean the bottom of a mortise. Usually, the bottom of the mortise is not cleaned as it is not visible once assembled. But for shrines, even the unseen parts receive plenty of care. The length of the blade is adjusted using a wedge.

Hopefully, we’ll be able to make some videos of them being used!

At Suikoushya, we share traditional Japanese woodworking techniques and skills. Since it is a small group system, we will provide guidance tailored to each individual’s skills, from beginners to woodworking professionals. Please join us!

I look forward to sharing fine woodworking with you.

One month Japanese woodworking classes